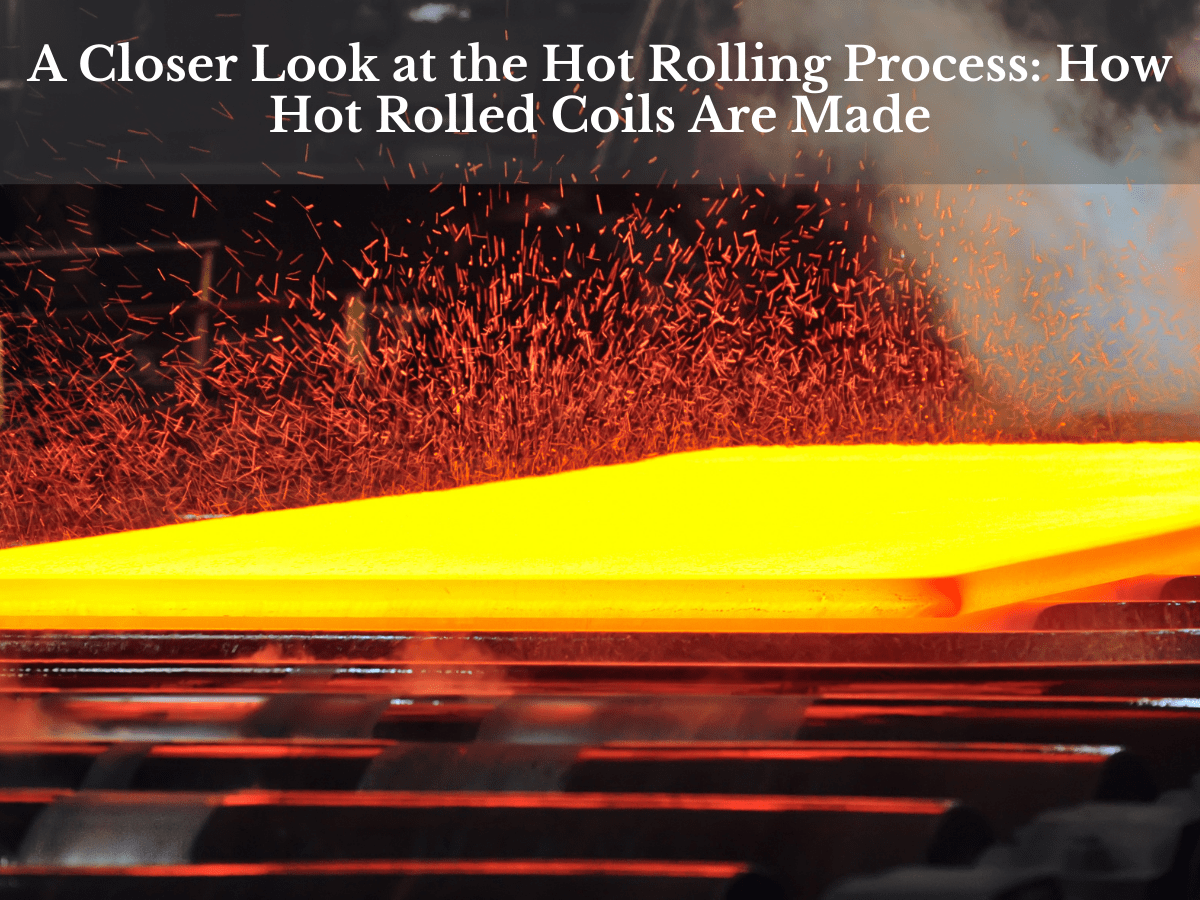

A Closer Look at the Hot Rolling Process: How Hot Rolled Coils Are Made

When it comes to innovative engineering and tools, you can rely on our organization and acquire Hot Rolled Coils at cheap prices that will easily match your needs and budget. Similarly, we are all familiar with this product, also known as black steel, which is formed by the hot rolling method.

Furthermore, this type of product is commonly referred to as general and welded structures, rerolling petrol and oil, pipe and tube, heavy vehicles, and many other titles. If you want to acquire fantastic quality hot rolled items for any reason, look no further because we will assist you in delivering the most effective sort of products to you.

It is currently the most popular product among all customers. As a result, if you’re eager to learn more about its benefits and method, you’ve come to the perfect site. In this article, we will go over the various procedures involved in the production of Hot Rolled Coils. If you’ve ever pondered how unique objects can be made, you’re not alone.

What materials are used to make a semi-truck and a water heater? There is just one answer to this question: hot-rolled items. Aside from that, this type of product might be more advantageous in the production of truck frames, water heaters, agricultural equipment, and guard rails. The main characteristics of our products are that they are classified as mild steel, which is why, without any compromise in quality, you can get the most unique hot-rolled solutions from us.

If you are considering using Hot Rolled Coils in building, machine manufacture, vehicle manufacturing, or for general reasons, you have come to the right place because this significant product may be used for a variety of uses. You can easily check the large choice of hot rolled steel after visiting our specific website and deciding to buy the best one based on your requirements. Thus, do not hesitate to explore our product range and place a quick purchase; we will do our best to deliver the products as quickly as possible.

Currently, the majority of consumers prefer hot rolled steel over cold rolled steel because of its efficacy and lower cost. We can quickly classify different types of steel thanks to our many years of knowledge easily we can classify different type of steel so no matter what kind of steel you want to buy anytime you can share your needs with us and happily we will like to deal with specific process of Hot Rolled Coils and deliver most satisfactory response to you.

When steel is rolled out into coils, it takes the place of hot rolled steel; thus, whether you want hot rolled steel or cold rolled steel, both will provide you with different types of benefits. Meanwhile, it is entirely up to you to decide what form of steel you want to use to take multiple pros.

Customers nowadays prefer to use this type of product since cold rolled steel is much more expensive than it, therefore, if you have a limited budget and want to enjoy the top quality of hot rolled products, we welcome you to join our expert team. The main point is that this type of product may readily assume the shape required, which is why we can claim that it is much more flexible than any other type of product.

If we talk about its process, then it commonly starts with heating slabs of steel to nearly 2300 degrees Fahrenheit. After that amount of heat directly affect the process of steel. At the same time, if there is a low temperature, it can create a defect in the material. Following this hot material, it would react with the oxygen in the air and convert into mill scale. This will also affect the surface quality of hot Rolled Coils and to remove the iron oxides, this material will also be sent to the mill scale cleanse.

This is the most important process in producing consistently high-quality hot rolled items. Simply by following this simple approach, you can choose the appropriate sort of hot rolled products and meet all of your steel needs.

The majority of clients choose this product since it has enhanced several parameters such as tensile strength, yield strength, and toughness. The one problem here is that we cannot do this at normal temperatures, which is why this process can only be done at really high temperatures.

If you are thinking about the microstructure and properties of steel, then you should go with this specific product. Meanwhile, we all know that rolling is classified by the temperature of the metal rolled that’s why here temperature plays a significant role and without it we cannot handle the procedure of Hot Rolled Coils to develop unique qualities of steel.

Because of technological advancements, this type of product can be sold quickly and moved to the next step, which means that it will provide you with a plethora of benefits in a short period of time. Furthermore, rolling processes often begin at high temperatures and are used to improve large deformations.

If you never want to encounter any flaws in this process, always strive to go with high temperatures, as its name suggests. Without it, you may not be able to complete the treatment efficiently, wasting both time and money.

Because of technological advancements, this type of product can be sold quickly and moved to the next step, which means that it will provide you with a plethora of benefits in a short period of time. Furthermore, rolling processes often begin at high temperatures and are used to improve large deformations.

Under this method to reduce the material and make it stronger, fast speed and high temperature are taken into account, as both are quite effective in resolving all complications of hot steel goods. If you wish to improve metal processing performance, Hot Rolled Coils should be more advantageous to you. At the same time, this can reduce energy usage and help you save money because the prices of these products are significantly lower.

Finally, hot rolling not only improves production efficiency but also maintains superior conditions for increasing rolling speed. We believe that the information provided above is sufficient to tell you about the unique technique of hot rolling and its key applications to the growth of your steel business.

Nonetheless, if you have any worries, please contact our professionals, who will explain the complete process of Hot Rolled Coils and you will quickly become totally confident in your knowledge of hot rolling.

Call for quick order

+234 803 225 4136